The lube kitchen series part 9: metal deactivators – oiling the wheels of corrosion control

This article has been supplied.

By: Steven Lumley - technical manager, WearCheck

(Virtual showroom) Metal deactivators play a key role in the fight against corrosion. This is the next focus in the ongoing discussion about lubricant additives, with condition monitoring specialist company, WearCheck.

Metal deactivators are another important additive in lubricating-oil formulations, especially with the growing use of non-ferrous metals, notably copper- and aluminium-containing alloys, that can be prone to the negative effects of staining and corrosion.

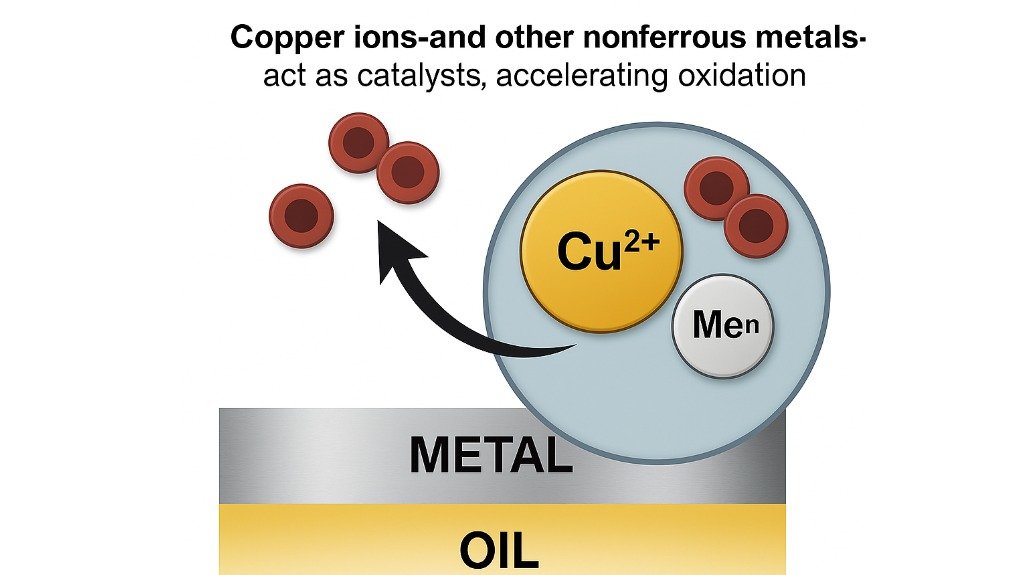

These metals (or more specifically their ions) are also catalytically active, and act as reaction sites that can trigger lubricant degradation through oxidation of the base oil.

Metal deactivators belong to the corrosion-inhibitor class of additives, and they work their magic on metal surfaces, especially non-ferrous metals, but also do their thing with wear particles that are dissolved or suspended in the oil.

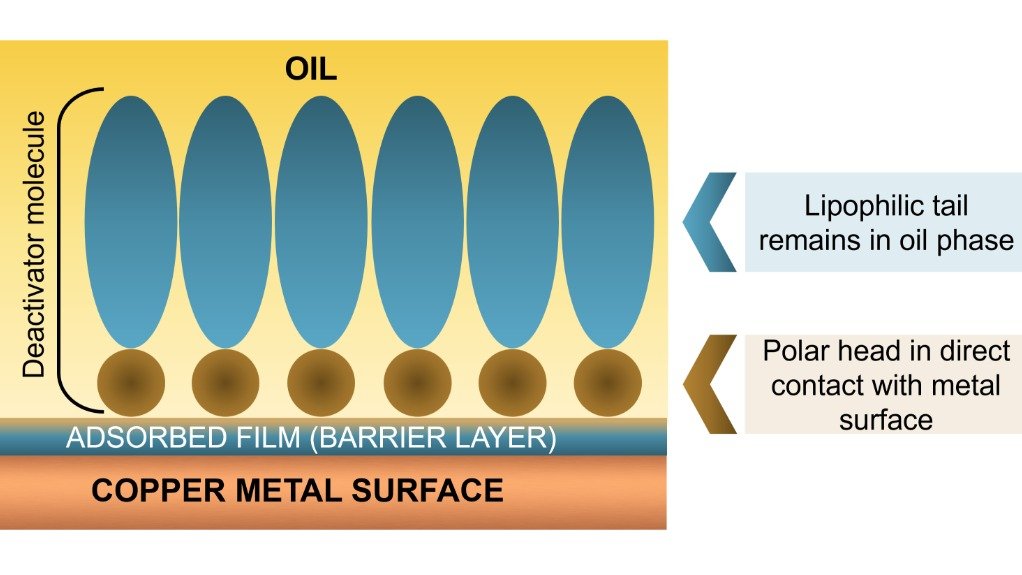

These specialised additives contain surface-active molecules that adsorb on metal surfaces. The best-understood mechanism for how they function involves the formation of an inactive barrier film that inhibits cathodic and/or anodic reactions that can accelerate oxidation and cause corrosion.

Metal deactivators are typically organic compounds that contain nitrogen or sulphur atoms. These atoms have a high affinity for metal ions and can form strong, stable bonds with them. This allows the additives to neutralise or deactivate these metal ions in the oil, which reduces their negative effects.

Lubricant blenders add metal deactivators to oils, primarily to protect copper and yellow metals in most automotive and industrial lubricants, including greases and metal-working fluids.

But wait - there’s more! The protective film that metal deactivators form on a metal surface is also thermally stable, water insoluble and chemically bonded.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation